REFERENCE STANDARD

UL444, UL1581, UL1666, IEC60332-1, IEC60332-3-24, EN50399

TEST STANDARD

ISO / IEC11801, ANSI / TIA-568-C.2

PHYSICAL PARAMETERS

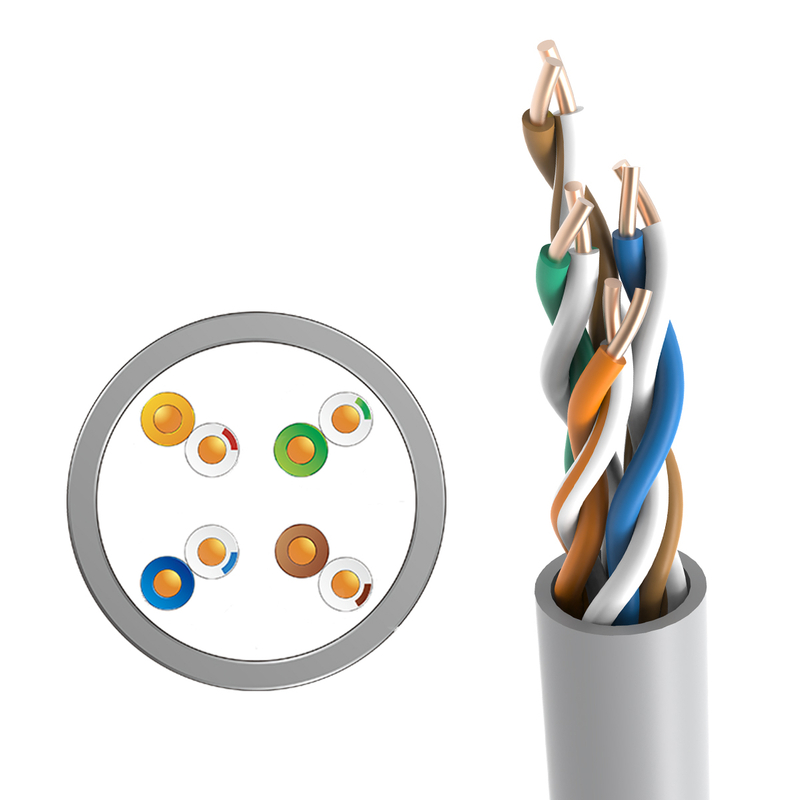

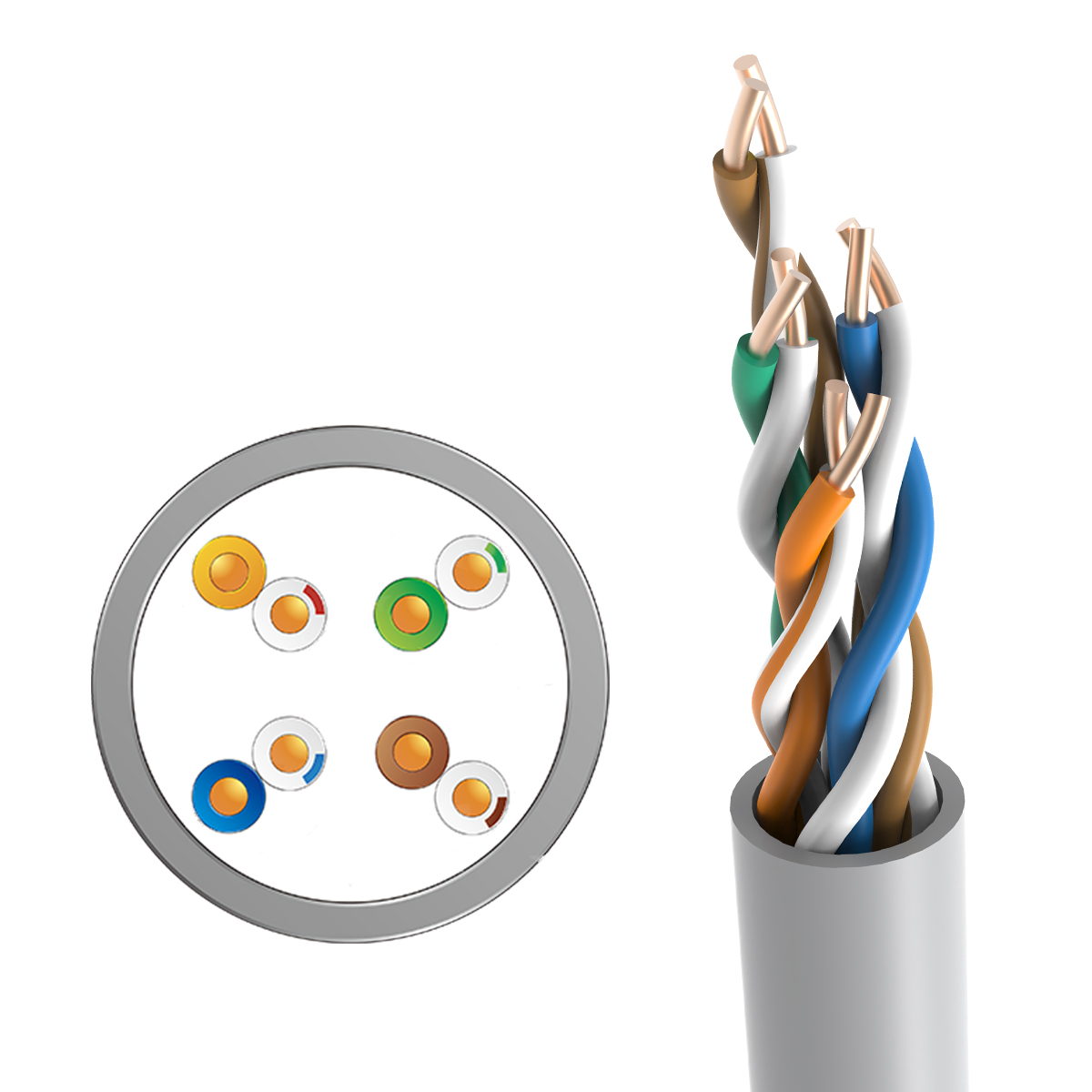

Conductor:

solid bare copper

Insulation material:

high density polyethylene

Insulation diameter:

0.88 ± 0.05mm (unshielded), 1.00 ± 0.05mm (shielded)

Shield:

Aluminum foil (total shield)

Braided shield:

tinned copper or aluminum magnesium alloy wire

Sheath diameter:

5.0 ± 0.4mm (unshielded), 6.2 ± 0.4mm (F / UTP shield), 6.6 ± 0.5mm (SF / UTP shield)

Sheath material:

PVC or LSZH low smoke halogen-free (according to different jackets), in line with RoHS and REACH requirements

Working temperature:

-30 ℃ to 50 ℃ (LSZH), -20 ℃ to 50 ℃ (PVC)

MECHANICAL PARAMETERS

Tensile strength before aging:

≥13.5Mpa (PVC), ≥10.0Mpa (LSZH low smoke halogen-free)

Elongation before aging:

≥150% (PVC), ≥125% (LSZH low smoke halogen-free)

Aging time:

100 ℃ × 24 hours × 7 days

Tensile strength after aging:

≥12.5Mpa (PVC), ≥8Mpa (LSZH low smoke halogen-free)

Elongation after aging:

≥125% (PVC), ≥100% (LSZH low smoke halogen-free)

Cold bending (-20 ± 2 ℃ × 4 hours):

8 times the outer diameter of the cable without cracking

Electrical Parameters

Transmission delay difference:

≤45ns / 100m

Transmission speed:

69%

Capacitance:

Maximum 5.6nf / 100m

DC resistance:

Maximum 9.5Ω / 100m

DC resistance unbalance:

maximum 5%

Unbalanced capacitance to ground:

maximum 330pf / 100m (shielded)

English

English

简体中文

简体中文